Production Standardization & Performance Dashboard

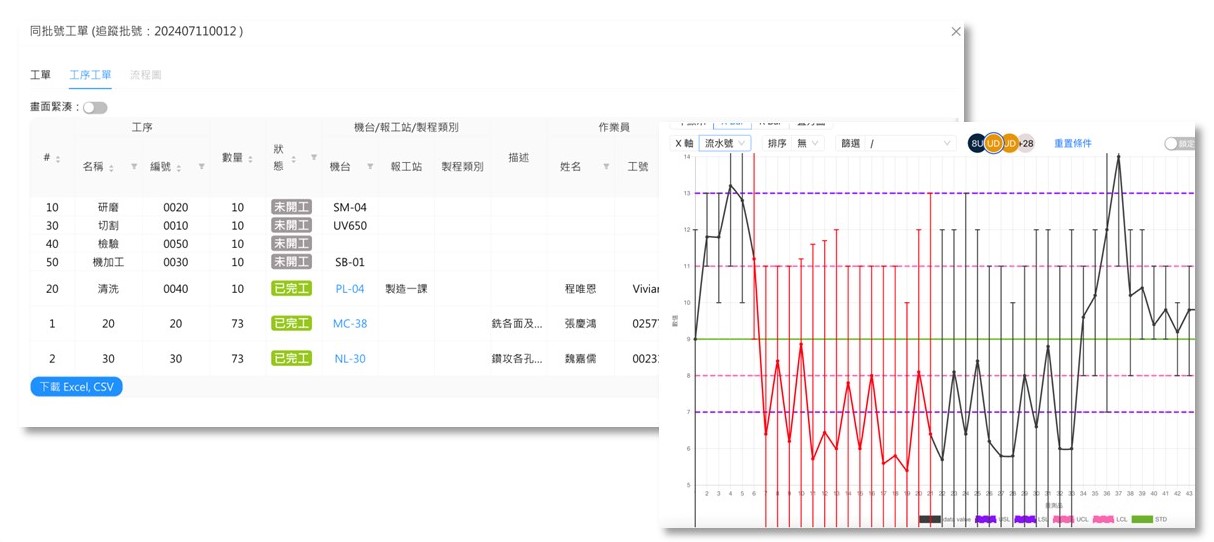

The lean production management system provided by DotZero supports ID tracking. By using note fields in work orders, ID numbers can be recorded during manufacturing, allowing for tracking the material ID and production parameters for production parameter analysis.

If there are abnormalities in process parameters in the SPC system, the corresponding material ID can be retrieved through the work order to achieve defective product traceability.

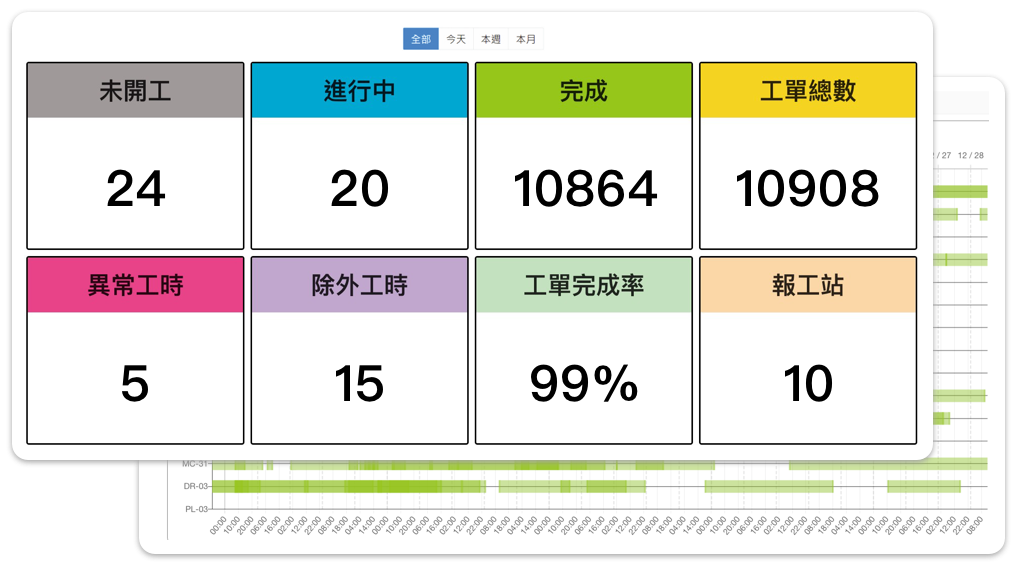

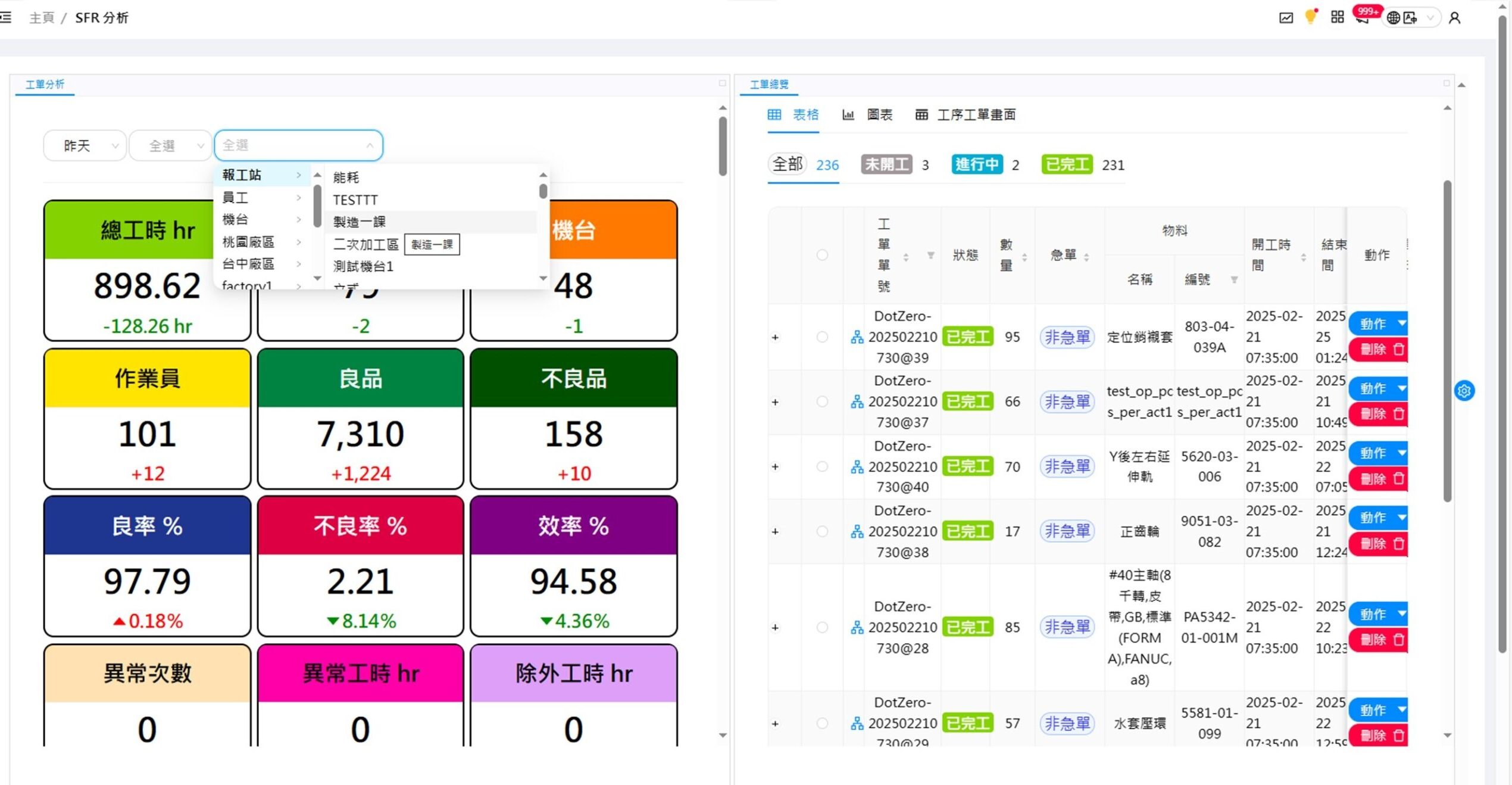

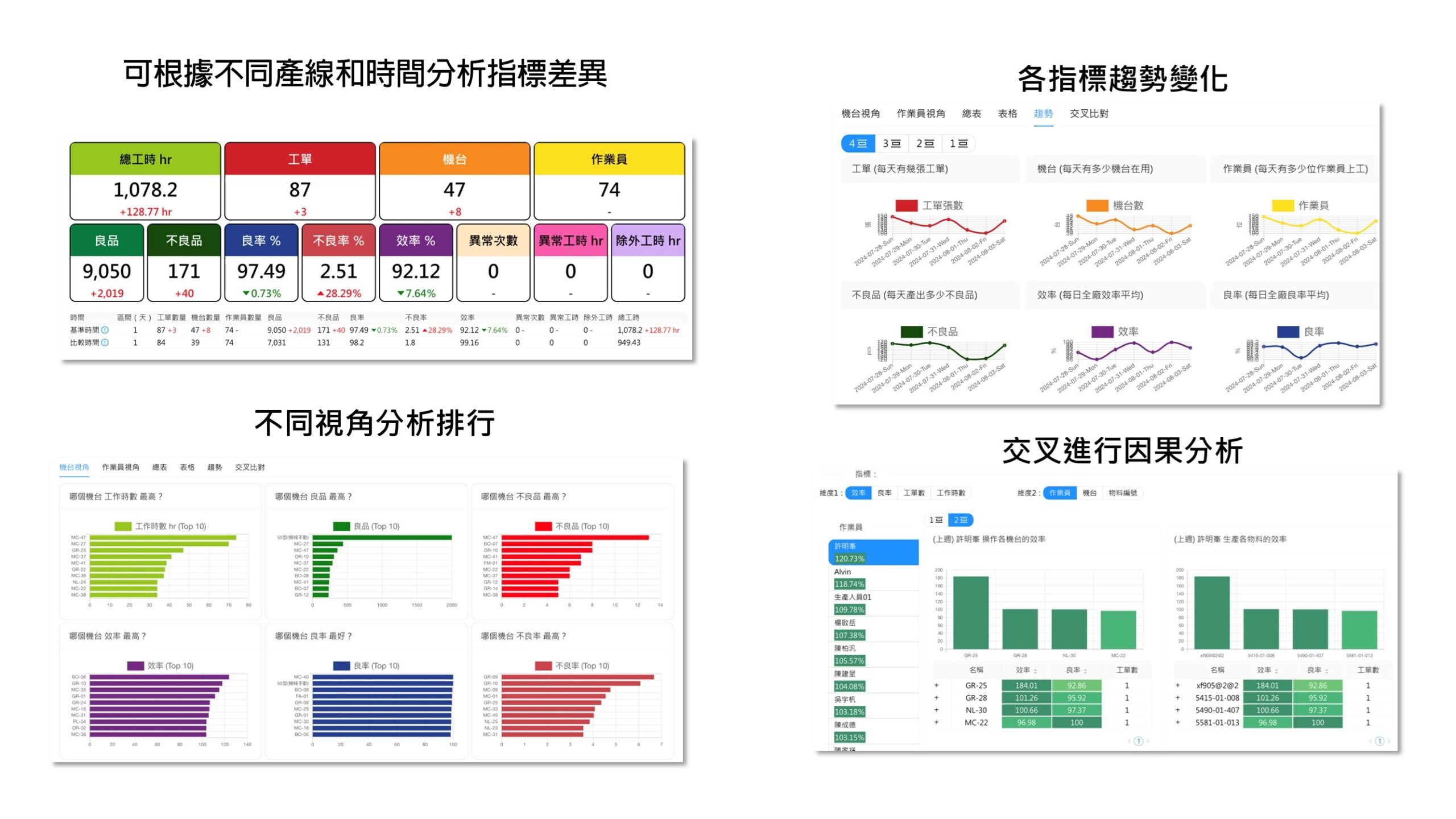

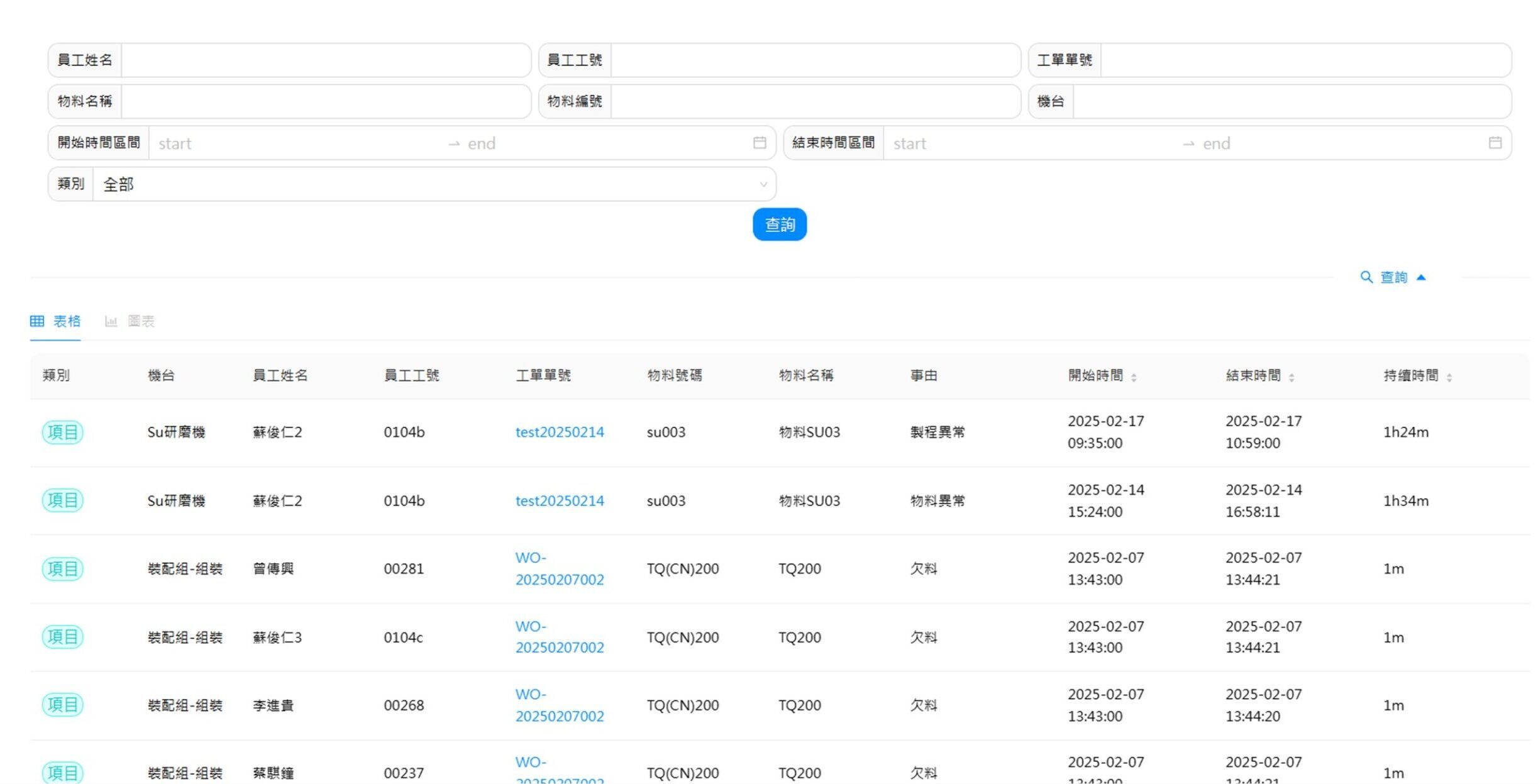

The SFR analysis feature allows users to filter by reporting station, operator, machine, plant, material, and time range to extract relevant work order production data. Key metrics such as good/defective product counts, downtime duration, number of incidents, and utilization rate can be visualized through charts. Frequently used charts can also be saved to personalized dashboards.

The SFR Lean Production Management System provides a variety of chart interfaces for tracking abnormalities. When a work order encounters an issue during production — whether reported by on-site personnel or automatically detected via IoT — the SFR system captures and records the event and its timestamp, offering precise traceability throughout the production process.

Defective products can be filtered and analyzed across different dimensions, allowing users to perform statistical analysis based on specific work orders, machines, or production lines.

To ensure comprehensive system maintenance and continuous updates, all DotZero Smart Manufacturing systems are provided through a subscription-based model. This approach offers highly flexible configuration options tailored to various production needs. During the subscription period, clients receive regular support check-ins and dedicated consulting services — enabling timely adjustments to the system interface and workflows for optimal usability.

生產標準化與人員績效提升戰情儀表板