Traditional monitoring relies on manual checks, which are time-consuming and prone to oversight. With high-resolution 360° imaging and AI-powered anomaly detection, the monitoring system captures real-time visuals of the production floor, improving both inspection accuracy and efficiency.

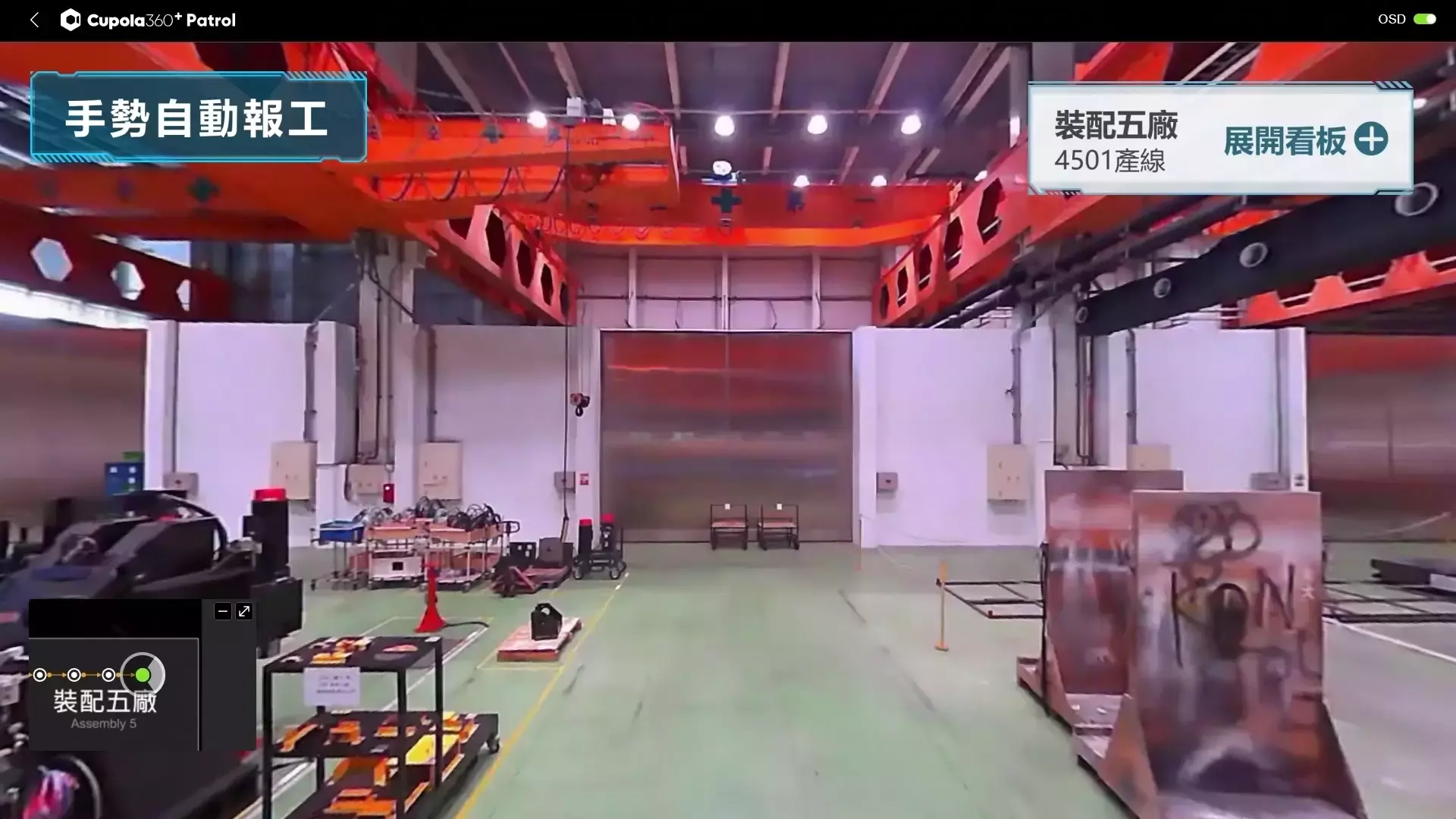

By integrating DotZero’s SFR Lean Management System with Cupola360’s visual data, this solution enables real-time collection and analysis of production information. Managers can monitor progress with intuitive dashboards and make decisions to keep production on track and ensure on-time delivery.

Safety is mission-critical. This solution continuously monitors equipment malfunctions or personnel without proper protective gear — and sends immediate alerts to prevent accidents and ensure a safer working environment.

To improve ease of use, the system supports gesture recognition. Operators can report work progress using simple hand gestures — reducing manual input, improving efficiency, and minimizing human error.